Casemaking Built for Two

Click on image for specifications and more features.

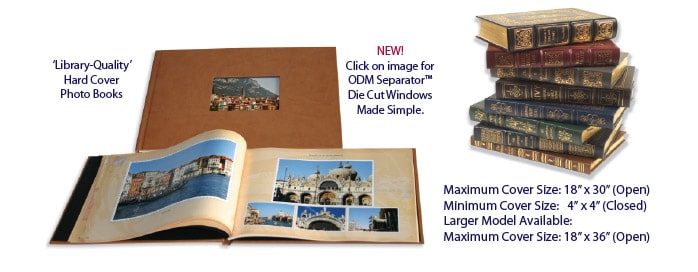

With the advent of on demand printing technology the book publishing business model has been changed forever. The initial solution for on demand books was a simple perfect bound paper back. Over the last few years, the on demand book market has evolved with many seeking a real book, that is, a hard covered edition that will last for generations to enjoy. It is for these reasons that On Demand Machinery choose to design and market a complete line of on demand hard cover binding machinery. Never before has the hard cover binding process been so simple. ODM has broken down the process to four easy steps that are simple to master. The first process is the Casemaking System which includes: the Spreader, Slider, Stomper and Squeezer. ODM equipment can help you begin to produce your own hard covered books.

The Spreader top side gluer comes equipped with an 18” glue roller. The cold PVA adhesive is placed in an easily removable glue reservoir. The thickness of adhesive is easily adjusted by a scraper blade. This unit is powered by a 115 volt, 60 cycle, 1/3 HP motor. The machine eliminates the need for the operator to flip over the glued cover material as with traditional bottom side gluers. This unit quickly disassembles enabling a fast and easy clean up.

The Slider case gauge makes the positioning of board material a snap! The arms will open to a maximum of 4”. The unit also comes equipped with an adjustable side guide and arm spacer kit for different joint gaps.

The Stomper air operated turning in machine is activated by depressing a foot switch. The climbing action of the turning in bar insures a tight corner wrap. Materials from leather to library buckram can easily be turned in with the Stomper. The machine is available in both 30” and 36” widths. Larger units can be custom made. The machine utilizes an external air source of 70 PSI.

The Squeezer rotary press will accept materials up to 18” in width by any length. The machine comes with a safety latch guard and delivery table. The squeezer rollers are adjustable for both pressure and gap opening.

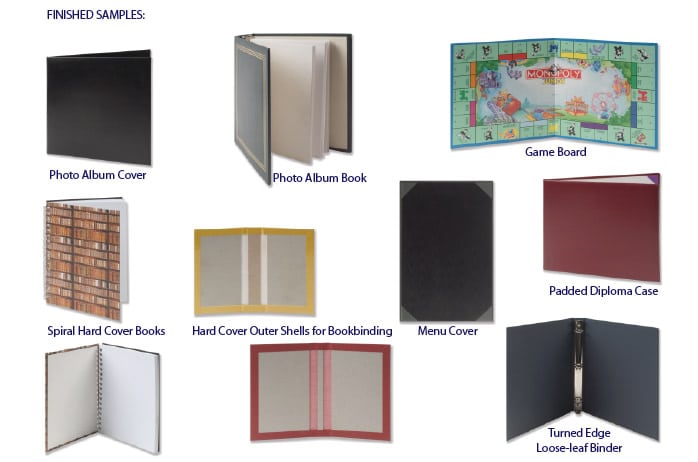

Ideal for hard cover bookbinding, photo books, menu covers, padded covers and turned edge loose-leaf binders.

During casemaking, the hard cover is produced that becomes the outer shell of the book. First start with a book cloth, or printed-paper. The operator sends the material through the topside gluer (Step 1 – Spreader), where a uniform coating of PVA cold adhesive is applied to the sheet. The freshly glued cover material is inserted into the sliding table case gauge (Step 2 – Slider) allowing the operator to accurately position all three cover boards that comprise the book cover. Once the cover boards are aligned, the operator inserts it into the air-operated turning in machine (Step 3 – Stomper) where all four sides of the cover material are turned in (wrapped around the edges of the cover boards). During the final step of casemaking, the finished cover is fed through the rotary squeeze press (Step 4 – Squeezer) where the cover is pressed to insure the cover material and boards are laminated.

Comments are closed.