| SPECIFICATIONS & TECHNICAL DATA: | ODM PANEL CORNER APPLICATOR™ | STANDARD EQUIPMENT for PANEL CORNER APPLICATOR™ MACHINE: |

|---|---|---|

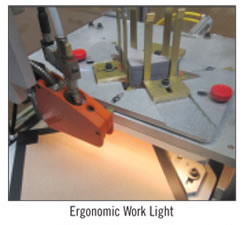

| Maximum Panel Size: Minimum Panel Size: Output (per hour): Floor Space: Net Weight: Power Required: | 8.5” x 14” 4.25” x 11” up to 180 panels 48” x 96” 500 lbs. 2 - 115 Volt, Single Phase 15 Amps, Air 100 PSI | • Easy-to-operate LCD touch screen color control panel • Corners accurately aligned prior to hot melt • Dynatec hot melt attachment applies a precise amount of adhesive glue in each menu corner • Foot pedal allows for efficient operation • Adjustable score pressure • Minimal make ready |

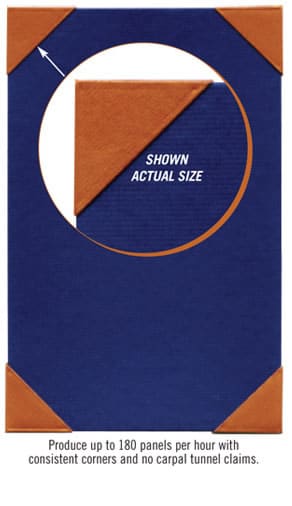

Machine Affixed Panel Corners Accurately Aligned Every Time!

ODM Panel Corner Applicator™ is a semi-automatic machine designed to apply accurately aligned corners to menu panel inserts. No more carpal tunnel claims. Speed up production with this once hand process.

ODM Corner Panel Applicator™ can apply 4 corners per 20 seconds; that’s up to 180 panels per hour.

STANDARD FEATURES:

• Easy-to-operate LCD touch screen control panel

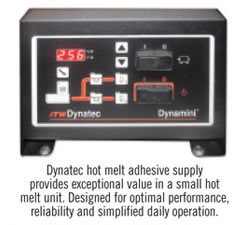

• Dynatec hot-melt supply unit provides exceptional value that’s designed for precision glue application.

• Consistent symmetrical corners applied every time.

• Adjustable score pressure

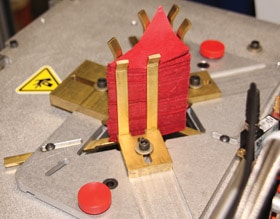

Menu panel is hand inserted into precision guides prior to depressing foot pedal cycle for panel corner application.

Comments are closed.